Ore Car Label Jig

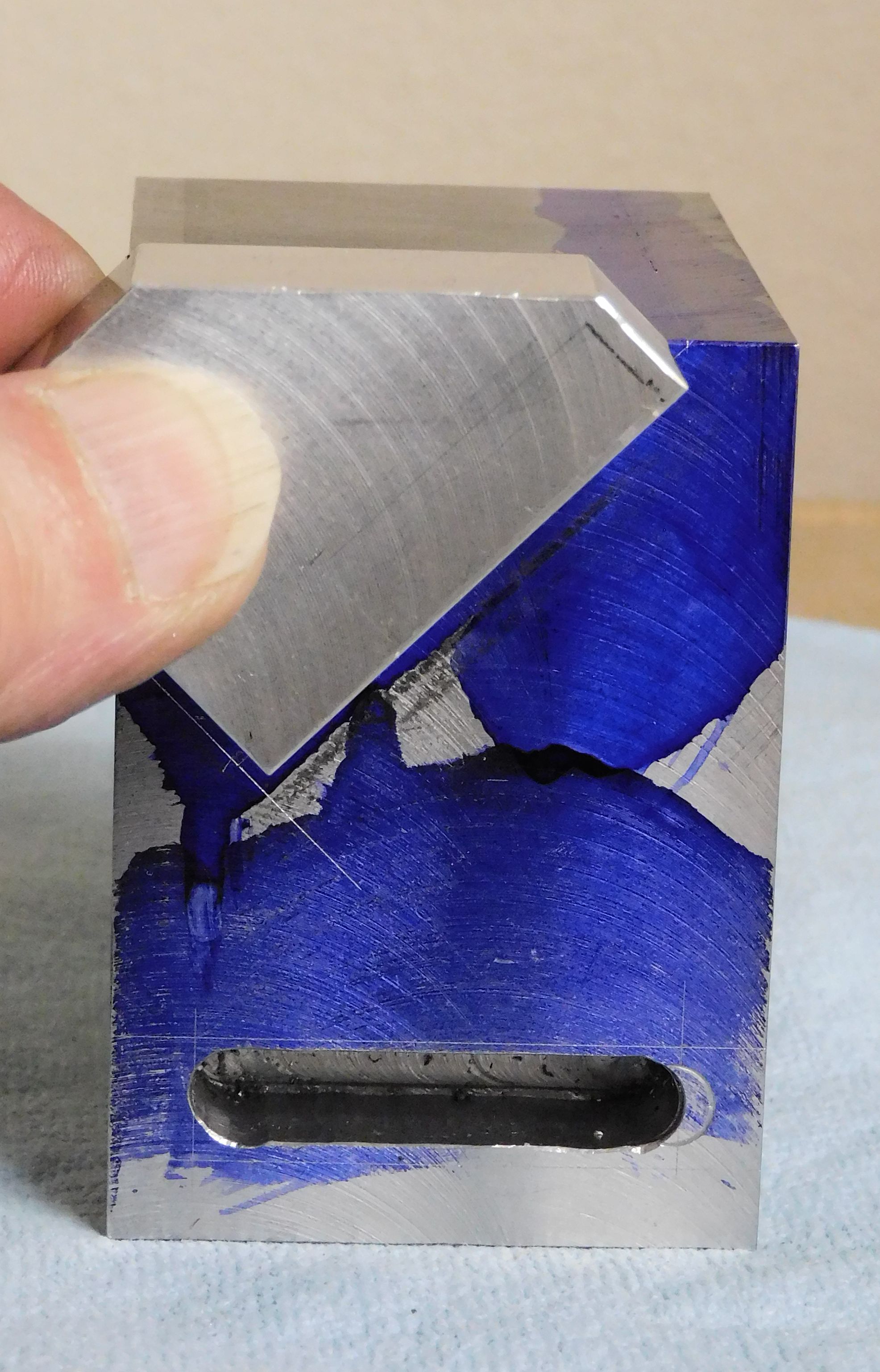

Every jig starts with a chuck of something. With some milling this chuck of steel is now a square rectangular solid.

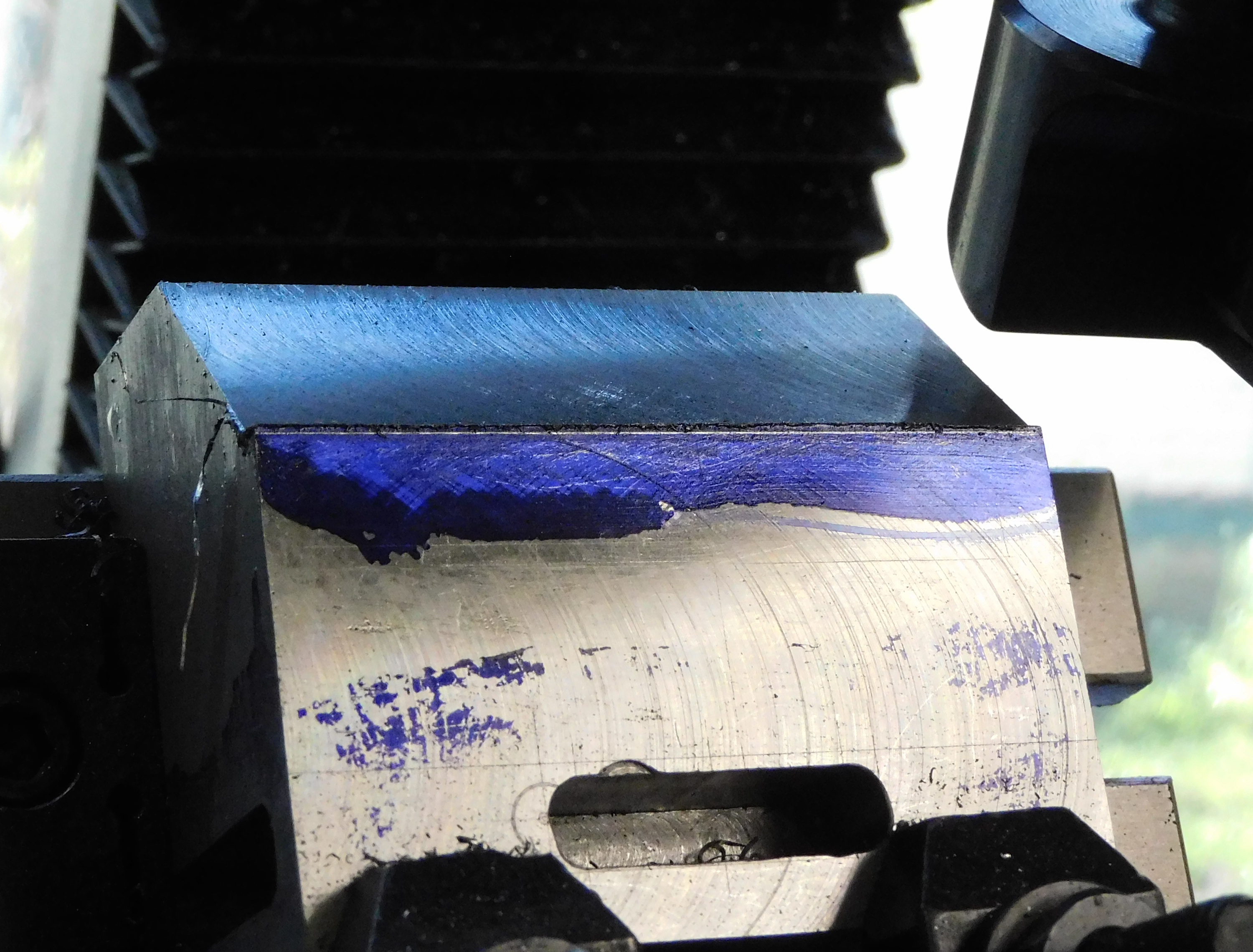

With some layout lines and hold down slots cut. Most of the top of the jig will be cut away so I'm going to uses "L" brackets in the slots to hold the jig in place on the rotary table while engraving on the sloped surface.

With the jig material mounted on the tilt table for milling, the metal to be removed is highlighted by the red arrow pointing to layout lines. I almost went to the bandsaw to cut off the top of the jig above the steel blue. Then I realized that the top edge, in the photo, would be lost as a reference. That edge is the only part of the jig I can easily use to orient the jig material before I start cutting. For the jig to be useful that top edge must be parallel to the x-axis of the mill (and perpendicular to the y-axis and z-axis). After much effort the 3" edge is in place within less than ±0.00025" end to end.

Needing to keep the top clear for cutting, clamping options are limited. Something more is needed to keep the jig from moving while cutting away all that metal.

No I don't have side clamps that will work with the tilt table's T-slots. Pause making labels to make a jig. Pause making the jig to making side clamps.

With the side clamps in place. Making chips down to the first line..